What is PSU material

2025-06-09 11:22:29

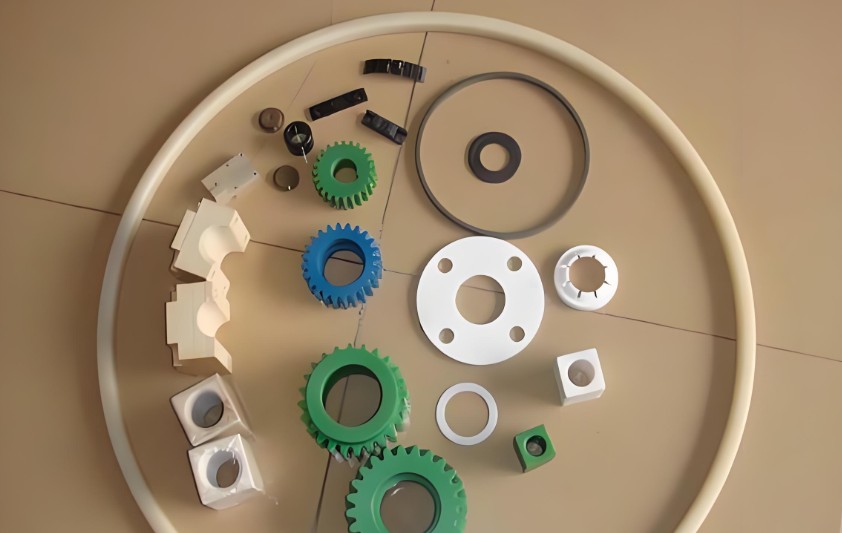

PSU

PSU (polysulfone) is a high-performance thermoplastic engineering plastic containing sulfonyl groups (-SO?-) and aromatic rings. Its rigid and stable molecular structure endows it with characteristics such as high temperature resistance, high strength, corrosion resistance, and excellent insulation.

High Temperature Resistance

Mechanical Strength

Chemical Stability

Resistant to acids, alkalis, salts, and most organic solvents (e.g., fuel), but soluble in polar solvents (e.g., dichloromethane).

Processing Characteristics

General-Purpose PSU

Polyethersulfone (PES)

High temperature resistance (180–200°C) and transparency, suitable for medical sterilization devices (e.g., surgical handles, dialyzers).

Polyphenylsulfone (PPSU)

Medical Health

Electronics and Electrical Engineering

Automotive/Aerospace

Food Industry