Injection mold Gate Types and Selection Guide

In injection molding, gates (the link between runners and cavities) directly impact melt filling, product quality, and processing

efficiency. As new-era injection tech advances in precision, efficiency, and intelligence, gate design/selection demands higher

standards. This article simplifies common gate types and guides scientific selection based on production needs and tech trends.

1. Common Injection Mold Gate Types

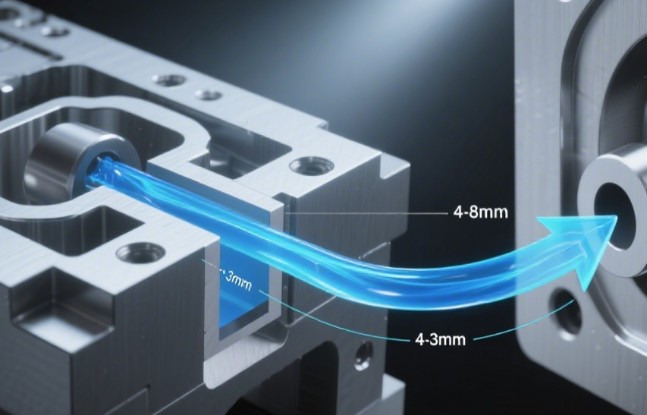

(1) Direct Gate (Sprue Gate)

Feeds melt directly from the sprue to the cavity, with dimensions 4–8mm (diameter) × 1–3mm (length). It minimizes flow resistance,

speeds filling, and suits large, thick-walled products (>3mm, e.g., plastic containers, auto bumpers).

Drawbacks: Hard to remove gate scrap (leaves large marks needing secondary processing) and causes high internal stress (unsuitable

for precision thin-walled parts).

(2) Side Gate (Edge Gate)

Machined on the mold’s parting surface, feeding from the product’s edge. Sizes: width 1.5–2× product’s max wall thickness,

thickness 0.5–2mm, length 1–3mm.

Widely applicable to most plastics and product shapes (especially small/medium multi-cavity molds). It controls filling speed/direction,

reduces stress, and allows easy scrap removal with minimal marks.

(3) Pin Gate

Small-sized (0.5–1.5mm diameter, 0.5–2mm length), feeding flexibly from the product’s top/other positions.

Ideal for appearance-critical products (toys, electronic casings) due to tiny marks. Enables automation (scrap separates automatically

when opening the mold).

Limitations: Requires a 3-plate mold (higher cost) and works poorly with low-fluidity plastics (PC, PMMA) – may need higher

pressure/temp, causing stress.

(4) Submarine Gate (Tunnel Gate)

Concealed in the product’s hidden areas, inclined to the cavity (1–3mm width, 0.5–1.5mm thickness, 2–5mm length).

Hides marks and enables auto scrap cutting; improves weld lines by adjusting melt flow.

Challenges: Difficult to machine (needs precise size/angle) and unsuitable for high-viscosity plastics (prone to poor filling).

2. Factors Affecting Gate Selection

(1) Product Factors

Shape/size: Direct gates for large/thick parts; side/pin gates for small/thin, appearance-critical parts; submarine gates for concealed

feeding.

Appearance: Pin/submarine gates for no obvious marks; side gates for lower demands.

Complexity: Multiple side gates for complex structures.

(2) Material Factors

Good-fluidity plastics (PE, PP): Any gate type.

Poor-fluidity plastics (PC, ABS): Direct/large side gates (avoid filling issues).

Heat-sensitive plastics (PVC): Direct/large side gates (speed up filling).

(3) Mold & Production Factors

Cost: Pin gates (3-plate mold, high cost); side/direct gates (2-plate mold, low cost).

Efficiency: Pin/submarine gates (auto scrap cutting, high efficiency); side/direct gates (manual scrap removal, lower efficiency).

3. New-Era Gate Selection Trends

Simulation tech (e.g., Moldflow): Predicts filling/defects pre-mold, optimizing gates and reducing test runs.

Adjustable gates (e.g., valve gates): Enable multi-product production on one mold, fitting small-batch, customized needs.

4. Conclusion

Gate selection depends on products, materials, molds, and production. With new tech, engineers should choose suitable gates to

balance quality, efficiency, and cost.